High Precision Machining/CNC Machining Milling Lathing /CNC Turning/Auto Parts

High Precision Machining/CNC Machining Milling Lathing /CNC Turning/Auto Parts Company description: We are a professiona

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | OEM |

| Size | Customized |

| Certificate | ISO9001 |

| Packing Details | PE Bag+ Cartons |

| Machining | Turning, Milling |

| Ssurface Treatment | Polishing, Deburring, Chrom Plate, Ni Plated, Zinc |

| Port | Shenzhen |

| Transport Package | Poly Bags+Carton(20X20X15cm) |

| Specification | ISO, DIN, AS/NZS, GB, ANSI and BS |

| Trademark | Zheng An |

| Origin | Guangdong China(Mainland) |

| HS Code | 7412209000 |

| Production Capacity | 1000 PCS Per Week |

Product Description

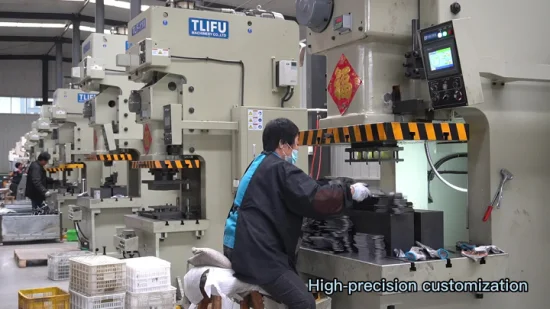

High Precision Machining/CNC Machining Milling Lathing /CNC Turning/Auto PartsCompany description:

We are a professional manufacturer and have over 10 years production and management experience in the field of fasteners ;

We have not only passed ISO9001 Quality certification system, but also adopted process quality managing system, we not only provide you with high quality products, but also are your industrial fastener solution supplier;

We can provide our customers with a good solution in the area of production design, production process, packaging and after-sale service.Customer satisfaction is our sole pursuit;

Product Description:

| Material | carbon steel, stainless steel, Aluminum,brass and so on |

| Tolerance | +/-0.002mm for metal material; +/-0.05mm for plastic material |

| Surface Treatment | Anodizing, chrome plating, silver plating, polishing, galvanized, electroplating, passivation, powder coating, spraying, and painting, etc |

| Main Process | CNC Machining, turning, lathe, milling, drilling, grinding, boring, stamping, threading, tamping, EDM, wire walking, laser cutting, laser marking, NC bending, and surface treatment |

| Quality Control | Strictly Quality control in the whole process, from material to packing Industry CT scanning, 3D projector, X-ray technoloty, Coordinate-measuring machine |

| Usage | Inspection & Electric Instrument, Medical Equipment, Construction Equipment, Home appliances field, etc. |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

Product Overviews:

PROCESS:

FAQ:

1. Are you a factory or a trading company?

A: We are direct factory and our production line covers all standards and non stands/special screws as per your requirement.

2. Where is your factory and how can I visit it?

A: Our factory is in shenzhen,Guangdong.

3. How long can I get some samples for checking and what about the price?

A: For samples we have in stock, we can send you some for free. If make new samples as per your specification, generally speaking, it takes around 5 working days.

The price of made to print samples will depends on the requirement of material, surface treatment, dimension, etc.

4.How to get an accurate quotation?

If you already have a sample at hand, please send us the existing samples, and we will quote to you once we receive the samples.

If there is no sample, please send us the drawing /print of the fastener, we will check all the specification including the dimension, surface treatment, material,

and our mechanical engineer will evaluate if it will be applied to production.

Related Products

-

![Customized CNC Metal Plastic Parts Precision CNC Machining Services]()

Customized CNC Metal Plastic Parts Precision CNC Machining Services

-

![Auto Spare Motorcycle Hardware Stamping Bushing CNC Machining/Turning Aluminium/Steel/ Titanium/Stainless Steel/Copper/Brass Automotive Metal Fabricaction Parts]()

Auto Spare Motorcycle Hardware Stamping Bushing CNC Machining/Turning Aluminium/Steel/ Titanium/Stainless Steel/Copper/Brass Automotive Metal Fabricaction Parts

-

![High Precision Customized Processing Accessories Metal Aluminum Alloy Stainless Steel CNC Machining Spare Parts Auto Parts]()

High Precision Customized Processing Accessories Metal Aluminum Alloy Stainless Steel CNC Machining Spare Parts Auto Parts

-

![0.005mm High Tolerance Customized Aluminum Auto CNC Machining Parts Casting Metal Motor Spare Parts Machining Service CNC Parts for Auto Car]()

0.005mm High Tolerance Customized Aluminum Auto CNC Machining Parts Casting Metal Motor Spare Parts Machining Service CNC Parts for Auto Car