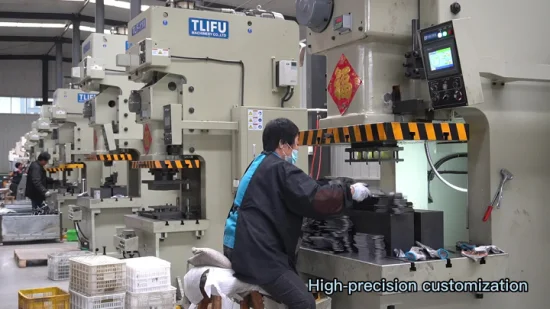

High Precision Custom CNC Lathe Machining Turning Milling Metal Stainless Steel Copper Brass Aluminum Auto Spare Machine Parts

Overview High Precision Custom CNC Lathe Machining Turning Milling Metal Stainless Steel Copper Brass Aluminum Auto Spar

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | FLM-CNC008 |

| Customized | Yes |

| Drawing Format | Igs, STP, X_T, Dxf, Dwg, PRO/E, Pdf |

| Process | CNC Tuming /CNC Milling/CNC Stamping/CNC Machinin |

| Type | Custom Precision CNC Lathe Parts(OEM Service) |

| Certificate | IATF16949/ISO9001/ISO13485/RoHS/Reach |

| Key Word | Stainless Steel Copper Brass Aluminum Auto Spare |

| Service | Custom Precision Fastener (OEM Service) |

| Lead Time | According to The Custmer′s Request |

| Customization | Yes |

| Tolerance | +/-0.003 mm |

| Delivery Method | by Sea, by Air or by Express Service |

| Surface | Zinc, Nickel, Chrome, Tin,etc. |

| Thickness | as Per The Customer′s Technic Drawing or Samples |

| Raw Material | Iron,Stainless Steel,Brass,Al,Copper,etc. |

| Usage | Home Appliances Parts, Automotive Spare Parts,etc |

| Transport Package | Plastic Bag+Carton+Plywood Pallet |

| Specification | as per the customer′s technic drawing or samples |

| Trademark | FULM/OEM |

| Origin | Shenzhen, China |

| HS Code | 850300909 |

| Production Capacity | 100000 Piece/Per Month |

Product Description

High Precision Custom CNC Lathe Machining Turning Milling Metal Stainless Steel Copper Brass Aluminum Auto Spare Machine PartsProduct Parameters| Parts Name | High Precision Custom CNC Lathe Machining Turning Milling Metal Stainless Steel Copper Brass Aluminum Auto Spare Machine Parts |

| Customization | Customized according to customer drawings. |

| Process | Lathe process |

| Parts Material | Stainless steel |

| Parts Coating | N/ A |

| Parts Color | Natural |

| Processing Degree | Micro Machining |

| Customization | OEM & ODM Service |

| Packaging | According to product requirements factory routine packaging or according to customer requirements. |

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm |

| CNC milling work range: 510mm*1020mm*500mm | |

| Inspection | IQC, IPQC,FQC,QA |

| Tolerance | +/-0.01mm ~ +/-0.05mm |

We not only produce spare parts processing for customers, but also provide product assembly services for customers. At the same time, we can quickly process prototypes and small batch production orders for customers without quantity restrictions, so as to greatly reduce development costs for customers. And quickly cooperate with customer products on the market.

We machine rapid prototypes and production low-volume metal parts for customers in multiple industries: aerospace, automotive, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.Measuring Equipment

2D Measuring Projector Hardness Tester Salt spray tester

Material spectrometer Electroplated coating thickness tester CCD automatic detector

Certifications

1. We cannot live without metal parts. We can find it everywhere we will be, it is integral part of cars, electronics, appliances, machines, communications, etc.

2. Metal parts quality is related to products' life. Whatever parts were consisted of the materials, but poor metal parts will influence its life. If metal parts are bad, it will lead to end products will not work.

3. But we often more focus on big and expensive parts, ignoring the small and important metal parts components.

4. Or put it another way, using 5% price to exchange 85% value. Choose a reliable supplier of metal parts, it will make sure stable and qualified goods. Hence protect end users' as most as possible.

We take every metal part seriously, its production, its quality, and its transportation. If you choose to cooperate with us, your team will be satisfied with our product in the future.FAQ

Q: Who we are?

A: Professional manufacturer specialized in metal parts which over 20 years of rich experienceQ: What can we do for you?

A:1) 100% local manufacturer 2) Best material selection 3) Best lead time and stable production 4) Rich experience on export business 5) Professional services 6. Quality control

Q: Why do you choose us?

A: Responsibility, Efficiency, Loyalty, Win-Win, Punctuality, Cost effectiveness

Q: When could we cooperate?

A: Whenever you want

Q: Where are we from?

A: We located at Shenzhen,convenient transportation

Q: How can customize products?

A: Attach your drawings with details(Suface treatment,material,quantity and special requirements etc).

Q: How long can I get the quaotation?

A: We will give you the quotation within 8 hours(Considering the time difference).

Q: How can I get a sample for testing?

A: We will provide free or charged samples depends on the products.

Q: How long will produce the parts?

A: Normally within 10 working days ,we will arrange the produce schedule depends on the quantity and the delivery.

Q: What's your payment terms?

A: We accept Paypal for small account, big amount, T/T is preferred

Q: How about the transportation?

A: Samples by air (if not too heavy),otherwise by sea or air

Q: What if the products we received are not good?

A: Contact us without hesitation,our special after-sales service will take the responsibilit