Plastic Parts Made by ABS, PP, POM, PC, Nylon, etc

Products: Plastic parts Material: ABS, AS, PA, PE, PP PVC, PC, PE, Nylon, EPDM, POM, EPT^ Surface Treat: Paint, texture

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | plastic parts 008 |

| Shaping Mode | Injection Mould |

| Surface Finish Process | Painting |

| Mould Cavity | Single Cavity |

| Plastic Material | ABS |

| Process Combination Type | Compound Die |

| Application | Household Appliances, Furniture, Commodity |

| Runner | Hot Runner |

| Design Software | AutoCAD |

| Installation | Mobile |

| Certification | CE, ISO |

| Standard | HASCO |

| Customized | Customized |

| Accuracy | +/-0.05 mm |

| Delivery Time | 10-25 Working Days |

| Cavity | Multi Cavity |

| Main Market | European Countries, USA etc. |

| Transport Package | OEM Plastic Parts |

| Specification | OEM |

| Trademark | OEM |

| Origin | China |

| HS Code | 3926909090 |

| Production Capacity | 500000 PCS/Month |

Product Description

Products: Plastic partsMaterial: ABS, AS, PA, PE, PP PVC, PC, PE, Nylon, EPDM, POM, EPT^

Surface Treat: Paint, texture

| Certification | ISO9001 |

| Size | Customized |

| Color | Any color |

| 3D,CAD drawing | Accepted |

| Temperature | -40°C to+300°C |

| Hardness | 30-95 shore A |

| Logo | OEM & ODM orders are welcomed |

| Tolerance | 0.05mm |

| Package | Standard package or according to your request |

| Feature | 1.Ozone and Chemical resistance 2. Anti-aging, good flexibility, good elasticity 3. Excellent oil resistance |

| Application | Electronic field, industrial machine & equipment,house-hold appliance,tele-communication,automobile,medical equipment industry etc. |

| Delivery | 10 days-20 days |

| Note | 1.Models and Logos can be Customized according to your Requirement 2.Designs and Specification are Accepted |

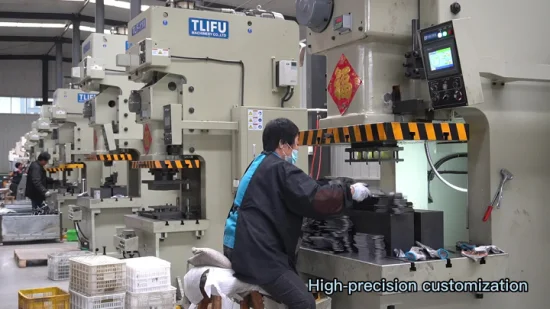

Fast delivery,high quality;

OEM,ODM welcomed;

high quality plastic material of POM, PE, PA, PVC, PP etc., high mechanical strength, rigidity, fatigue resistance, resistance degeneration good shape. Excellent wear resistance, dimensional stability, creep resistance, good abrasion resistance, self-lubricated and frictionand dielectric properties, water resistance and solvent resistance. It's an ideal replacement material for non-ferrous metal and alloy steel of copper, cast zinc, steel, aluminum and other metal materials. POM together with UHMWPE, PA, F4 are known as the four wear-resistant plastic materials. High thermal stability, good chemical stability and excellent electrical insulation. It is the first material choice for manufacturing gear. Apply to produce gears, springs, bearings, connecting rod, impeller blades, toys, windows, water tanks and washing basins of the industry in machinery, automobile, electronic and electrical.

Specifications:

material: POM, PA, PE, PVC, PP etc.

color: white, black, blue

surface: smooth/smooth

tensile strength: 30-80Mpa

density: 1.2-1.5g/cm3

impact strength: 80-100KJ/m2

moulding shrinkage: 2.5%-2.8%

resistivity: 1x10^14ohm.cm

cold temperature: -30°C

heat distortion temperature: +165°C

size: as per the buyer's drawing or sample

quantity: 10pieces

Related Products

-

![OEM Manufacturer Aluminum/Zinc/Brass/Alloy Metal/Steel/Iron Gravity/Sand/Die Casting Part]()

OEM Manufacturer Aluminum/Zinc/Brass/Alloy Metal/Steel/Iron Gravity/Sand/Die Casting Part

-

![CNC Machining Welding Milling Casting Precision Black Zinc CNC Machine Part Milling Part Medical Machine Parts]()

CNC Machining Welding Milling Casting Precision Black Zinc CNC Machine Part Milling Part Medical Machine Parts

-

![CNC Center Machining CNC Anodized Aluminum Other Electric Bicycle Parts Custom Auto Parts]()

CNC Center Machining CNC Anodized Aluminum Other Electric Bicycle Parts Custom Auto Parts

-

![A380 Aluminum Alloy Die Casting Part Sand CAS Mold Cast and Low Pressure Castings]()

A380 Aluminum Alloy Die Casting Part Sand CAS Mold Cast and Low Pressure Castings