Customized/OEM High Precision Aluminum/ Stainless Steel/SPHC/SPCC Sheet Metal Stamp Stamped Stamping Part for Car/Automobile/Machinery/Truck/Trailer Part

Package size per unit product 50.00cm * 20.00cm * 30.00cm Gross weight per unit product 0.150kg Customized/OEM High Prec

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | As your drawings |

| Processing Type | Metal Spinning |

| Material | Stainless Steel |

| Mould | Multistep Progressive Dies |

| Surface Processing | Spraying |

| Fine Blanking | Multi-Position |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.01mm |

| Customized | Customized |

| Item | Stamped Parts |

| Technics | Stamping |

| Part Type | Stamp Parts |

| Export Markets | Global |

| Shipping Port | Qingdao |

| Place of Origin | China |

| Transport | by Sea or Air |

| Packing | Wooden Cases or Carton |

| Surface Treatment | Spraying/Polishing/Galvanized/Electroplating |

| Weight | Customized |

| Sample | 7 Days Ready |

| Processing | as Per Your Drawing |

| Materials | as Per Request |

| After-Sale Service | Definetly |

| Certificate of Origin | as Per Request |

| Transport Package | Plywood Box |

| Specification | As your requirement |

| Trademark | jufeng |

| Origin | Weifang City, Shandong Province, China |

| HS Code | 7326199000 |

| Production Capacity | 50000PCS/Month |

Packaging & Delivery

Package size per unit product 50.00cm * 20.00cm * 30.00cm Gross weight per unit product 0.150kgProduct Description

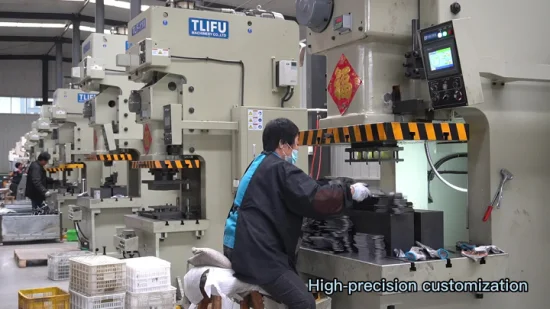

Customized/OEM High Precision Aluminum/ Stainless Steel/SPHC/SPCC Sheet Metal Stamp Stamped Stamping Part for Car/Automobile/Machinery/Truck/Trailer partAdvantages:1. We are ODM&OEM, design according to your drawing.2. Rich experience and good technology support( have engineers with more than 20 years experience).3. Manufacturer and Trade Company.4. Low MOQ is accepted.5. 100% inspection before delivery.6. Competitive price with high quality.7. Convenient transportation.

| Material | Aluminum 6061, 6063, Stainless Steel, Iron, brass |

| Processing Craft | Drawings→ mould making → stamping →rough machining → CNC machining (if need) →surface treatment →product checking→ packing →delivery |

| Tolerance | ± 0.02mm |

| Surface Treatment | Electroplating, Chrome Plating, Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating, Sandblasting, Passivation, Spray painting, Etc. |

| Quality Assurance | ISO9001:2015 Certified, SGS Certification |

| Inspection | 1.Foundry in-house: 100% inspection on critical dimension; 100% on appea rance. 2.Third Party inspection available upon requirement. |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection |

| Quality Guarantee | 3 years |

| Features & Advantage | 1.High machining accuracy, the flatness within 0.1mm. 2.High strength and not easy to deform, has good electrical and thermal conductivity. 3.High finish appearance, smooth surface roughness is Ra3.2 after machining. 4.The machining precision is high and the assembly structure is seamless. 5.No granules, no spots and no painting peel off in appearance. |

OUR PRODUCING PROCESS: 1. Tooling (Mold) design and Manufacture. 2. Manufacture the parts according to the Stamping Machine. 3. Riveting, Welding or Screw tap according to Customer's require. 4. After finish manufacture process we will test the parts by the Image measurement instrument, Caliper, Angel Gage etc. 5. After make sure all the dimension can reach customer's require, we will make the surface treatment process. 6. After finish surface treatment we will testing all the parts by worker so that we can make sure the parts which we sell is 100% qualified. 7. After finish testing we will pack the parts by Vacuum Package Machine.

1).We remain profitable and sustainable even through the current economic downturn, in part though our market diversification,and in part due to our conservative philosophy guiding the way we have done managed our business since 2000. |

2).We continue to offer innovative cost-reduction options at the design stage and value-added/value engineered cost savings for our customer's current products. |

3).We listen to our Customers and add systems,processes,equipment or facilities constantly to meet the needs and requests of our customers. |

4)While these key indicators are a "Given" today, we track, monitor and implement changes to always improve our goals as we strive to improve in everything we do. |

5)Our commitment to quality is backed up by third party certification to world class quality standard ISO/TS 16949:2002. We offer the global OEM market quality distinction in manufacturing,innovative & engineering. |

Company Mission Statement |

"Support our customers by providing innovative,cost effective, engineered solutions,prototypes, components and assemblies, enabling our respective business partners to achieve superior financial results and quality growth." |

Establish a challenging and enjoyable workplace environment to promote teamwork.

|

Material Acceptable

| Aluminum | AL5052, AL6061, AL6063,AL7075 etc. |

| Stainless steel | SS201, SS303, SS304, SS316 etc |

| Brass | C36000 (C26800), C37700 (HPb59), C38500 (HPb58), C27200 (CuZn37), C28000 (CuZn40) etc |

| Bronze | C51000, C52100, C54400, etc. |

| Iron | 1213, 12L14, 1215 etc |

| Steel | Q235, 20#, 45# etc. |

Quality First,Price Best,Service Foremost!We assure you of our best services at all times!IIf you are interested in our products, please send message to us!

Related Products

-

![30 Years Manufacture Aluminum/Stainless Steel/ Sheet Metal Stamping/CNC Machining/Welding/Bending Spare Part for Auto Parts/Furniture/Machine]()

30 Years Manufacture Aluminum/Stainless Steel/ Sheet Metal Stamping/CNC Machining/Welding/Bending Spare Part for Auto Parts/Furniture/Machine

-

![Custom Hot Die Carbon/Alloy/Aluminum/Stainless Steel Forging Part in Construction Machinery/Agricultural Machinery/Vehicle/Valve/Auto/Machinery Part]()

Custom Hot Die Carbon/Alloy/Aluminum/Stainless Steel Forging Part in Construction Machinery/Agricultural Machinery/Vehicle/Valve/Auto/Machinery Part

-

![Aluminum Machining Auto Parts 5 Axis CNC Stainless Steel Machining Parts]()

Aluminum Machining Auto Parts 5 Axis CNC Stainless Steel Machining Parts

-

![Hot Sale Customized High Precision Brass Pinion Spur Gear, Aluminum CNC Parts. CNC Machining Parts]()

Hot Sale Customized High Precision Brass Pinion Spur Gear, Aluminum CNC Parts. CNC Machining Parts