Stainless Steel Processing Hardware OEM Stretch Forming Parts Sheet Metal Stamping Casting Part Sheet Metal Stamping Metal Stamping Stamping Parts

Deformation process of deep drawing The coordinate grid test method was used to analyze. During deep drawing, the blank

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | st-n89 |

| Process | Forming Process |

| Industry | Metal Stamping Parts |

| Tolerances | 0.01mm |

| Customized | Customized |

| MOQ | 10 |

| Surface Treatment | Electroplating/Spraying/Polishing/Oxidation/Galvan |

| After-Sale Service | 24 Hours |

| Delivery | Sea, Air, or Express |

| Quality | Excellent |

| After Warranty Service | Video Technical Support, Online Support |

| Transport Package | Polybag Lnner+Export Carton Outer |

| Specification | customized |

| Origin | Hebei |

| Production Capacity | 500000 |

Product Description

| 1. Raw Material | Copper, phosphor copper, Brass, Stainless steel, Aluminum, steel, spring steel, Nickel-Silver... and all different kinds of metal; |

| 2. Surface treatment | Gold / Silver /Tin / Nickel / Zinc / Chromium / Copper-plating / Laser etching/Screen printing/Phosphating (can pass salt spray testing with 160 hours)/Black coating / Painting/ Power coating /Electrophoresis / Passivating /Deburring / Polishing / Brush according to ROHS standard; |

| 3. Quotation | Please provide the Formal drawings (normally, with DWG/STP/PDF file ), and make notes with material/QTY/surface treatment and any other requirements, we will provide you the quotation sheet within 48-72 hours; |

| 4. Prototype & Mould | We make the prototypes or molds according to the drawings confirmed by both of us and the customers! The lead time depends on the structure and qty of parts, Normally, the lead time for prototypes is 3-15 days; the lead time for mold is 10-25 days; |

| 5. Production | We will provide samples according to the drawings to customers for approval. Then arrange the production and confirm the delivery date according to the Purchase Order; Normally, the lead time for production is 5-30 days, the structure of parts is different, and the lead time will be different. |

| 6. Package | Plastic bags; Preserving Box; Reel/tape package; Plastic tray; Wood box; Export carton and any other customized package according to the customers' requests. |

Deformation process of deep drawing

The coordinate grid test method was used to analyze. During deep drawing, the blank holder first compresses the medium plate blank, and the punch goes down, forcing the material (flange part) under the blank holder to produce plastic deformation and flow into the gap between the punch and the die to form the side wall of the cylinder. After deep drawing, it is found that the bottom mesh is basically unchanged, and the simple wall part changes greatly.1. the concentric circles with the same original spacing form a circumferential line with the same length and increased spacing. The closer to the cylinder mouth, the greater the spacing.2. the original radiation lines with equal division become vertical parallel lines with equal spacing.3. radial elongation deformation and tangential compression deformation of flange materialSummary: the deformation of deep drawing materials mainly occurs in the flange part. The process of deep drawing deformation is essentially a process in which the material at the flange produces plastic deformation under the action of radial tensile stress and tangential compressive stress, and the flange shrinks continuously and turns into the cylinder wall. This degree of deformation is the largest at the outermost edge of the flange.

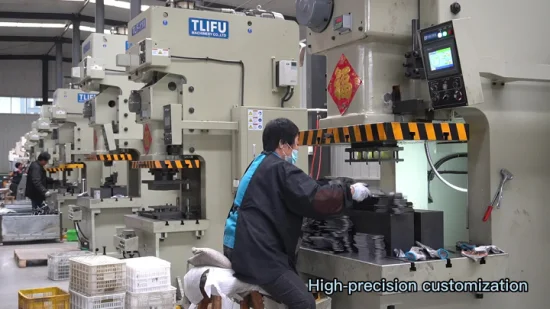

We can produce and process the stamping parts according to your requirements of materials, specifications, shapes, surfaces, packaging ( and so on).Here are our advantages:1. Several years of experience in producing and processing stamping part2. Facilities: plenty of various machines, such as stamping machines, automatic stamping machines, punching machines, oil hydraulic pressing machines, bending machines, welding machines, meter lathes, and so on3. Materials: Carbon steel, stainless steel, copper, brass, aluminum, and so on4. We produce and process products of high quality. We try our best to provide you with the products you required. We sincerely hope that we can establish great business relationships with you. Why Choose Wobeide:

1. At least 10 years of working experience in the industrial hardware fittings industry.2. All products are made of high-quality raw materials with guaranteed quality.We do 100% inspection before shipment.4. SGS certification is provided.5. Provide professional products according to customer requirements, save time and cost for you, and enjoy one-stop shopping.6. Call at any time, professional technical staff 24 hours online to answer your questions7. Professional after-sales service guidance.

1. What is the minimum quantity of your orderWobeide: The minimum order quantity is 100 units.2. How can I receive samples?After you pay, we send it to you by express3. What is your warranty? Do you have any proof of that?Wobeide: We are SGS certified, quality first.Are you a businessman or a manufacturer?Wobeide: We all are. Wobeide makes products and is allowed to import and export products.

Please feel free to contact us and we will reply within 24 hours.

Related Products

-

![OEM Manufacturer Aluminum/Zinc/Brass/Alloy Metal/Steel/Iron Gravity/Sand/Die Casting Part]()

OEM Manufacturer Aluminum/Zinc/Brass/Alloy Metal/Steel/Iron Gravity/Sand/Die Casting Part

-

![Stainless Steel Precision Aluminum CNC Metal Machined Machine Machining Part CNC Machined Part CNC Part]()

Stainless Steel Precision Aluminum CNC Metal Machined Machine Machining Part CNC Machined Part CNC Part

-

![High Precision CNC Turning Ashtray Lid with Sandblasting and Anodizing Finishing]()

High Precision CNC Turning Ashtray Lid with Sandblasting and Anodizing Finishing

-

![Customized Precision Aluminum Stainless Steel Part CNC Machining Parts for Testing Equipment]()

Customized Precision Aluminum Stainless Steel Part CNC Machining Parts for Testing Equipment