CNC Tools Manufacturer Small Metal CNC Lathe Brass Copper Pipe Fittings Custom CNC Precision Machined Parts

Overview Features of CNC parts1. Precision CNC parts strictly according to customers' drawing,packing and quality reques

Send your inquiryDESCRIPTION

Basic Info

| Condition | New |

| Certification | CE, GS, ISO9001 |

| Standard | DIN, ASTM, JIS |

| Customized | Customized |

| Material | Aluminum |

| Application | Metal Recycling Machine, Metal Processing Machinery Parts, Metal forging Machinery, Metal Casting Machinery |

| Lead Time | 1-4 Weeks Depends on Requests |

| Tolerance | +/-0.002mm, or Customized |

| Roughness | Ra0.2-Ra3.2, or Customized |

| Transport Package | Foam, Carton |

| Trademark | Raycool |

| Origin | Shanghai |

| HS Code | 8479909090 |

| Production Capacity | 500000/Year |

Product Description

| Our Processing | CNC machining, CNC milling and turning, drilling, grinding, stamping, tapping, |

| Surface finish | Hard Coating/Black Anodize/ Clear Anodize/ Hard Chrome /Clear Zinc/Plasma Niride |

| Tolerance | 0.005mm |

| QC System | 100% inspection before shipment |

| Drawing format | CAD / PDF/ DWG/ IGS/ STEP/So |

| Packaging | Standard package / Carton box or Pallet / As per customized specifications |

| Testing equipment | CMM (Coordinate Measuring Machine), Height gauge, Caliper, Hardness tester, Roughness tester, Projector machine, Pin/Angle/Block/Plug/Thickness/Thread/Radius gauge, etc. |

| Trade terms | EXW, FOB, CIF, As per the customer's request |

| Shipment Terms | 1) 0-100kg: express & air freight priority |

| 2) >100kg: sea freight priority | |

| 3) As per customized specifications | |

| Note | All CNC machining parts are custom-made according to the customer's drawings or samples, with no stock. If you have any CNC machining parts to be made, please feel free to send your kind drawings/samples to us anytime by email. |

| Surface Finish | Anodized/Zinc/Nickle/ZiNi plating |

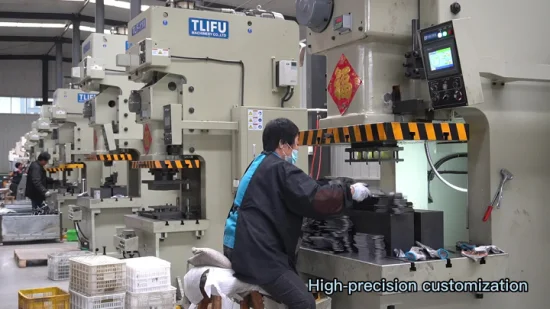

Features of CNC parts1. Precision CNC parts strictly according to customers' drawing,packing and quality request2. Tolerance: Can be kept in +/-0.005mm3. 100% inspection during production to ensure the quality4. Experienced technology engineers and well trained workers5. Fast and timely delivery. Speedy & professional service6. Provide customer professional suggestion while in the process of customer designing to save cost.7. Quality assurance in accordance with ISO9001Company Profile

Shanghai Raycool IndustrialOur company offers variety of products which can meet your multifarious demands. We adhere to the management principles of "quality first, customer first and credit-based" since the establishment of the company and always do our best to satisfy potential needs of our customers. Our company is sincerely willing to cooperate with enterprises from all over the world in order to realize a win-win situation since the trend of economic globalization has developed with anirresistible force.

CertificationsFAQ

1.

Q: What is the processing for the quote?

Q: How is the next?

A: We will send the cost to you and get your confirmation for the quote;3.

Q: What software will you use for the proceeding?

A: We make the 3D program with Pro-Engineer, UGS, SOLIDWORKS, MASTERCAM, etc ;4.

Q: what is the type of machine for manufacturing?

A: Manufactured from CNC Machining, Laser cutting, stamping, injection as well as the parts files different ;5.

Q: Do you do surface treatments, please?

A: Yes, sure. we do the surface treatments, for instance: Powder coating, Anodizing, Galvanized, Electroplated, Laser etching as well as painting ;6.

Q: What is the quality Control before shipping?

A: We have QC department for the quality control before shipping;

Related Products

-

![CNC Tools Manufacturer Small Metal CNC Lathe Brass Copper Pipe Fittings Custom CNC Precision Machined Parts]()

CNC Tools Manufacturer Small Metal CNC Lathe Brass Copper Pipe Fittings Custom CNC Precision Machined Parts

-

![Customized Plastic Injection Molded Plastic Parts Manufacturer]()

Customized Plastic Injection Molded Plastic Parts Manufacturer

-

![Aluminum Machining Auto Parts 5 Axis CNC Stainless Steel Machining Parts]()

Aluminum Machining Auto Parts 5 Axis CNC Stainless Steel Machining Parts

-

![China Roof Tile Galvanlume Stone Coated Metal Roofing Materials Tiles Roof Sheet]()

China Roof Tile Galvanlume Stone Coated Metal Roofing Materials Tiles Roof Sheet